Products and Technology

Integrated LED Applications

Integrated LED Applications

Introduction and Application

Technical Capabilities

Light Application

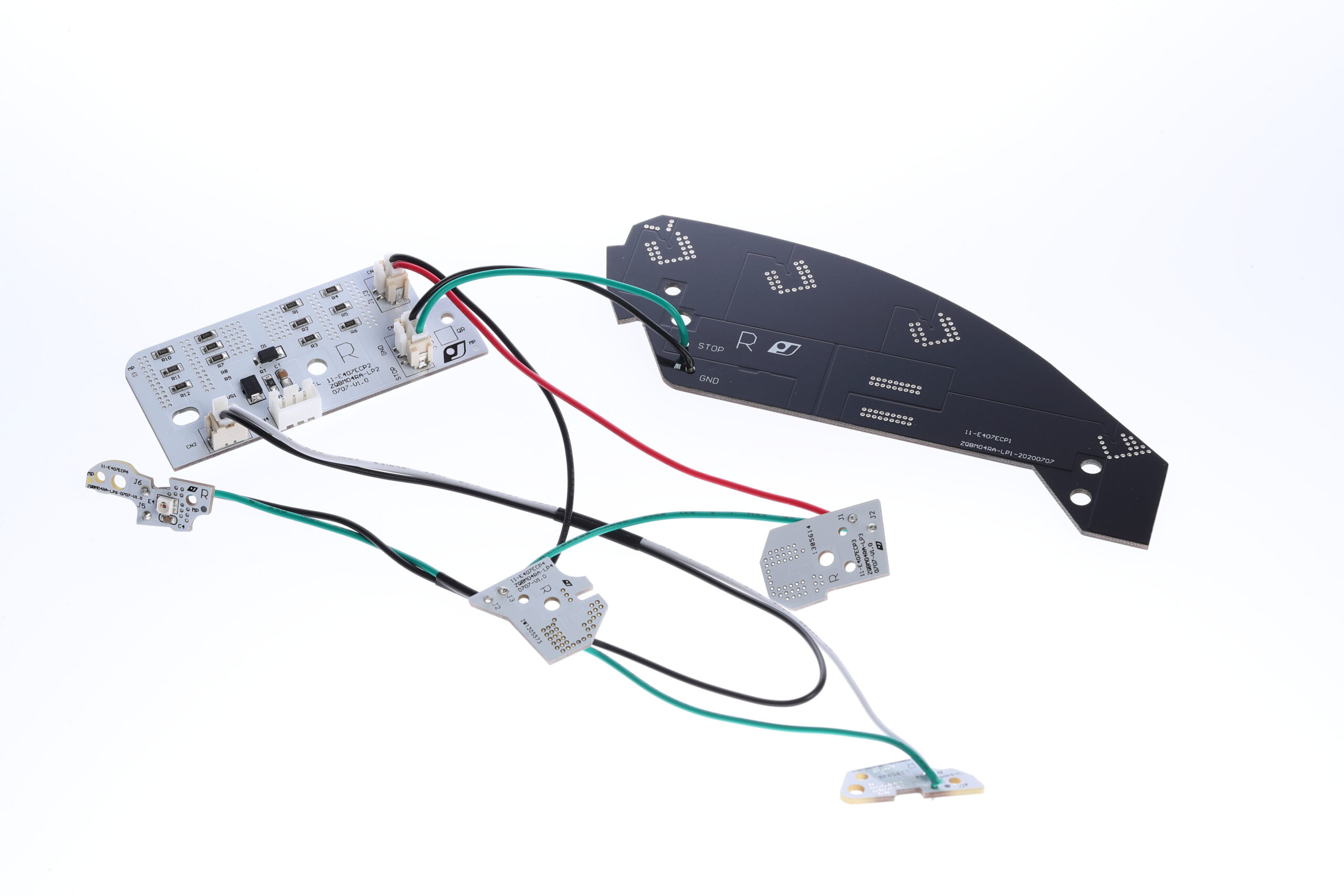

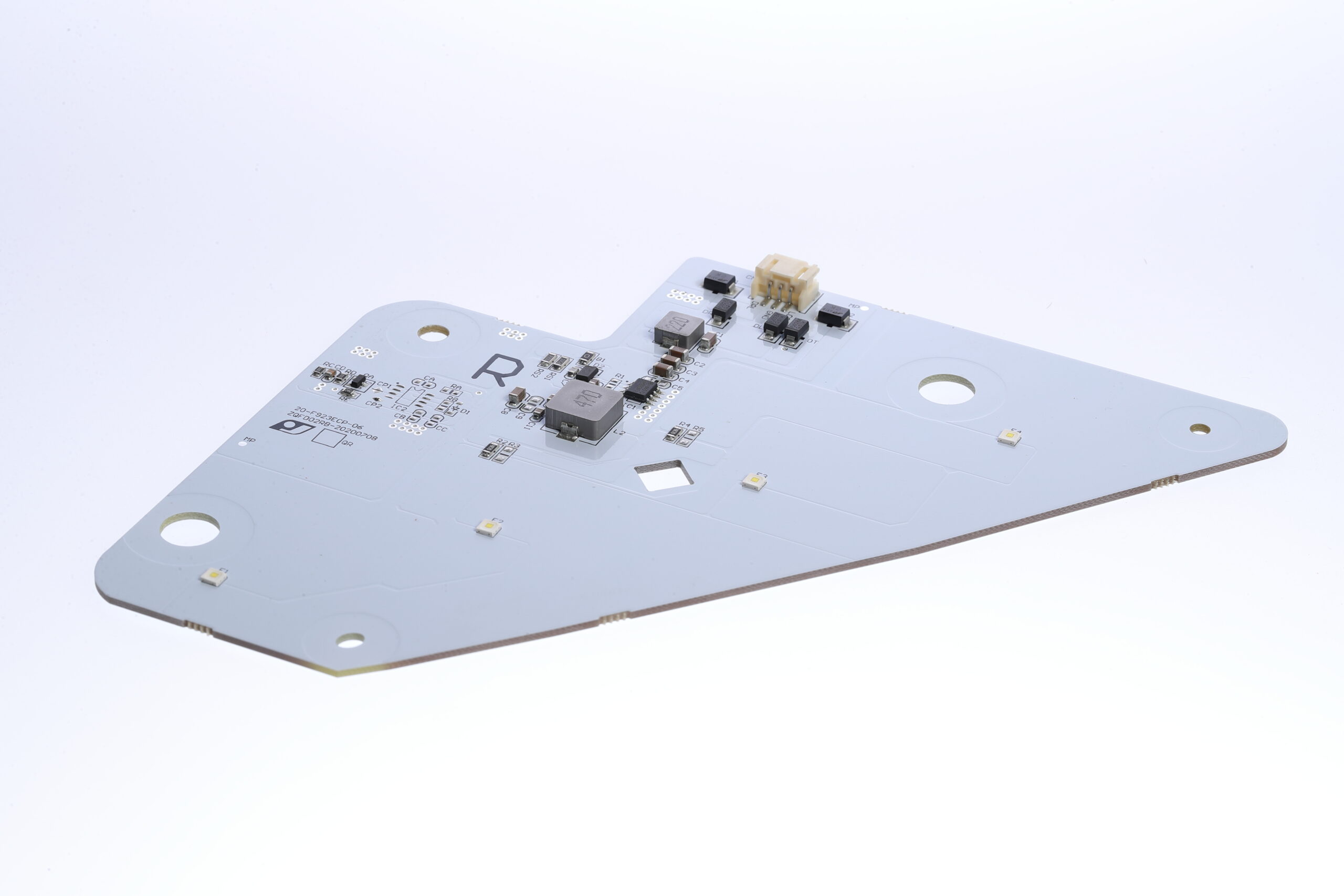

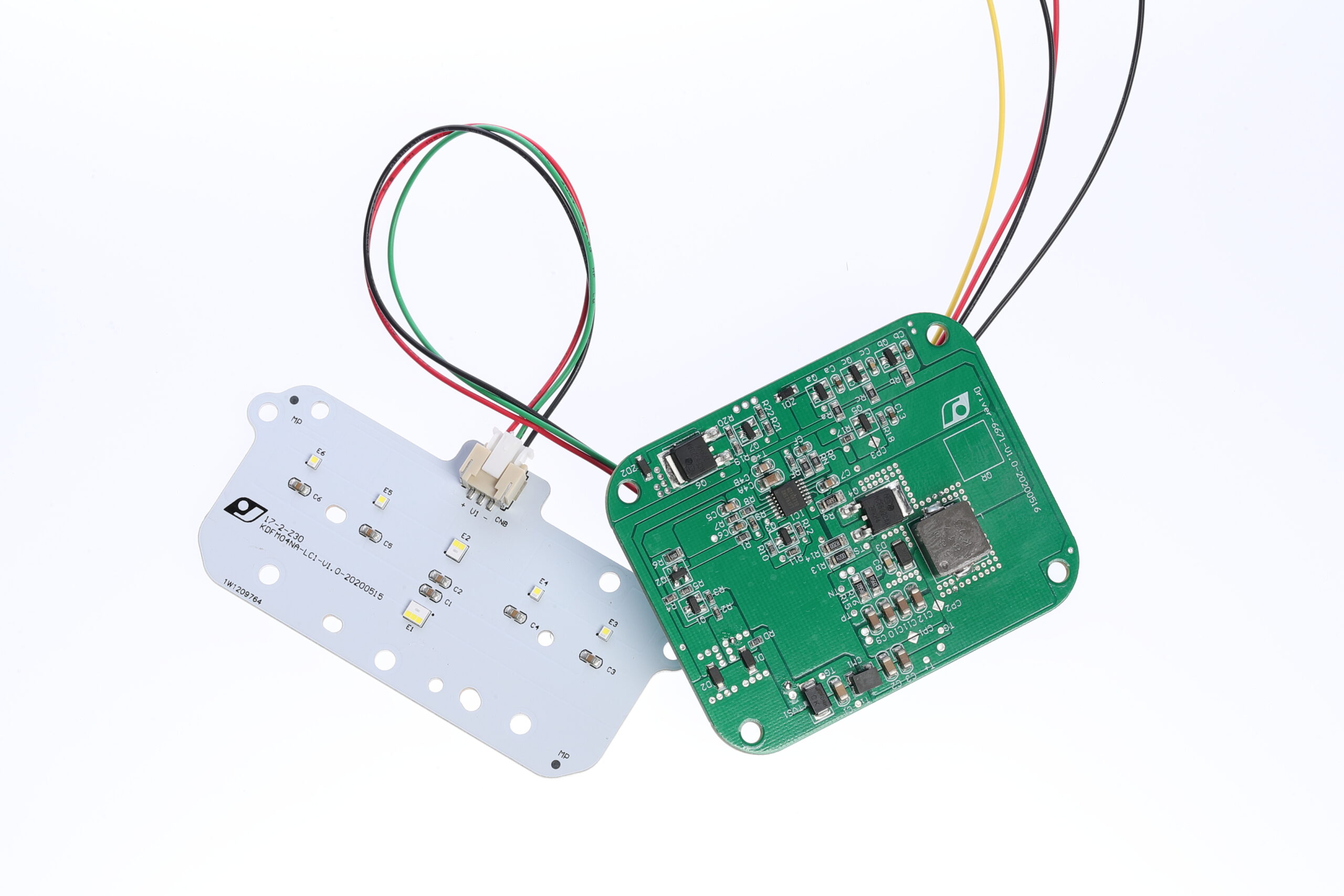

One-Stop Integrated LED Automotive Lighting Module Solution A comprehensive solution that efficiently integrates key components—including flexible printed circuits (FPCs), rigid PCBs, wire harnesses, and mechanical parts—into a complete LED automotive lighting module. This solution offers: Efficient Power Distribution: Optimized power paths to reduce energy consumption. Superior Signal Integrity: Ensures stable transmission of high-speed communication and control signals. Long-Term Durability: Robust construction designed to withstand harsh automotive environments while maintaining reliable performance.

Smart Handheld

Consumer Electronics

automotive electronics

Surgical Robotics

other electronics

Key Characteristics (with PCB Integration)

- Routes low-voltage DC power (12V, 24V, 48V) and control signals (PWM, DMX, DALI, CAN, etc.) to LED PCBs.

- Supports parallel, series, or hybrid wiring depending on the LED array design.

- Direct Termination: Wires soldered to PCB pads or through-holes.

- Connectorized Interfaces: Plug-and-play mating with board-mounted headers (JST, Molex, TE Connectivity, etc.).

- Flex-to-PCB Transitions: Hybrid designs where a flex circuit mates with a rigid PCB via harnessed cables.

- Strain Relief & Overmolding: Reinforcement at the PCB connection point to prevent solder joint fatigue.

- Available in custom lengths, wire gauges, and connector types for PCB-specific layouts.

- High-temperature insulation for LED thermal zones.

- Optional shielding and grounding to reduce EMI between LED driver and PCB.

- Protective jackets, sleeving, or potting for outdoor or harsh environments.

- Pre-terminated assemblies snap directly into PCB connectors.

- Color-coded wiring simplifies PCB alignment and reduces assembly errors.

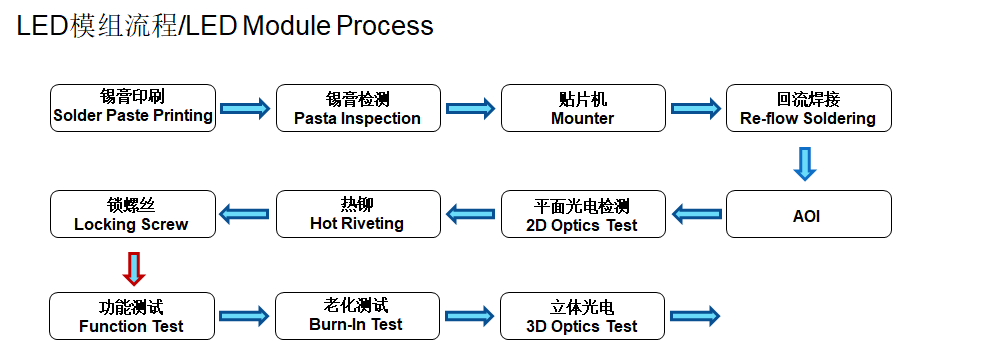

Process Overview

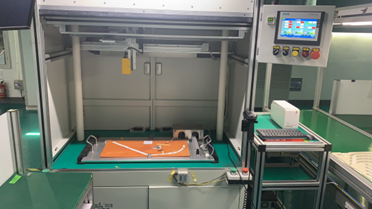

Solder Paste Printing

Solder Paste Inspection

Surface Mount

2D Optics Test

AOI

Re-flow

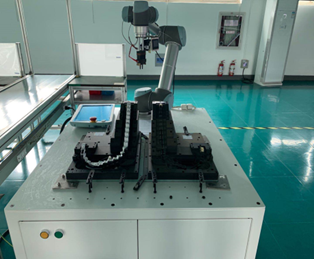

LED Module Process

Heat Staking

Assembly Integration

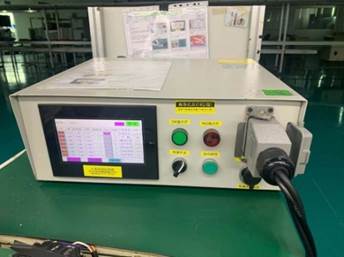

Function Test

Inspection

3D Optics Test

Surface Finished