Products and Technology

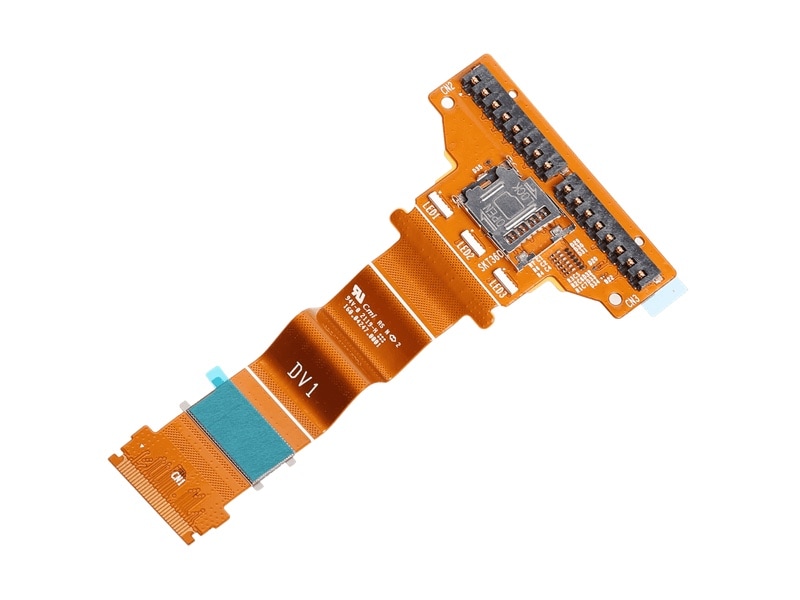

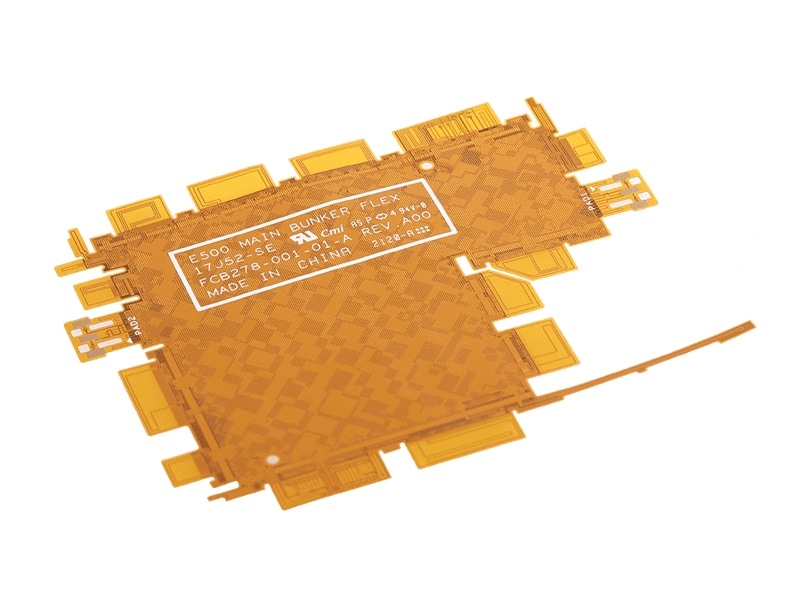

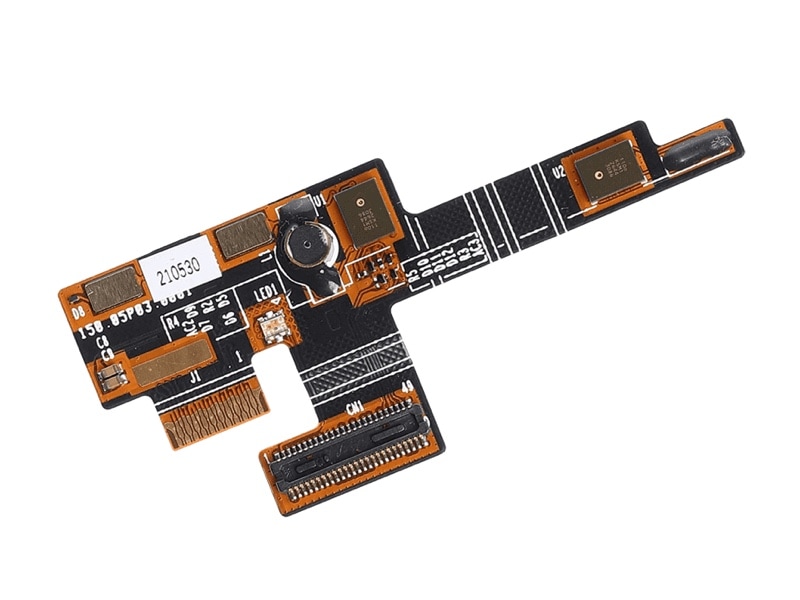

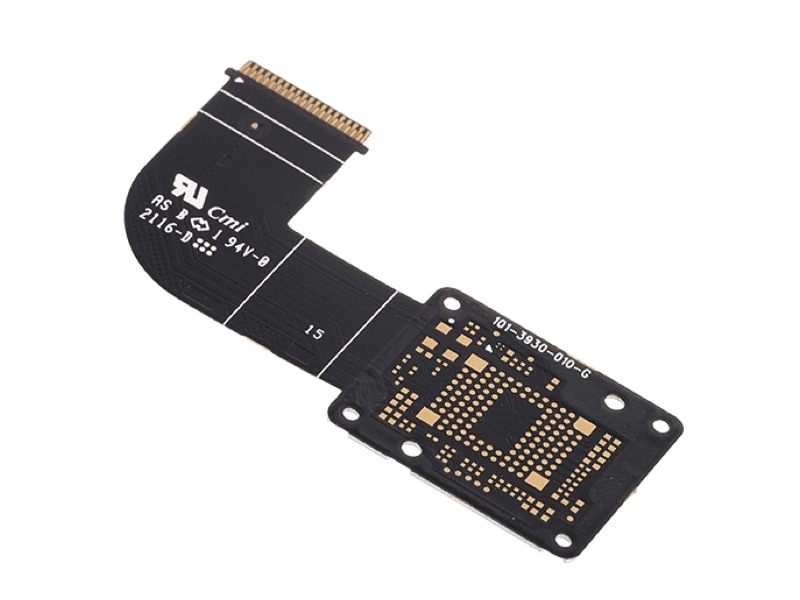

FPC

FPC

FPC Application

1.Static Flexible Circuit Board (often just called a “static flex”) is a type of flexible printed circuit (FPC) designed for applications where the flex circuit will be bent or folded only once or a few times during assembly, but not repeatedly during its service life.

2. Dynamic Flex Circuit (also called a flexible printed circuit for dynamic applications) is a type of flexible circuit designed to withstand continuous, repetitive motion during the product’s operational life.

3.Integrated Flex Circuit to Cable Assembly combines the benefits of flexible printed circuits (FPCs) with traditional wire or cable harnesses into a single interconnect solution. This hybrid design is used when certain parts of the system benefit from the precision, thin profile, and reliability of a flex circuit, while other areas require the ruggedness, strain relief, or long reach of standard cables.

Smart Handheld

Consumer Electronics

Automotive Electronics

Surgical Robotics

Display Electronics

Product Features

- High Flexibility Design: Can bend, fold, and twist without damaging conductors, ideal for complex structures.

- 3D Conformability: Can be installed on three-dimensional shapes and in confined spaces, overcoming the limitations of rigid boards.

- Lightweight Advantage: Significantly lighter compared to rigid boards or wire harnesses.

- Reduced Failure Risk: Fewer connectors and solder joints minimize mechanical interface issues, enhancing system reliability.

- Vibration and Fatigue Resistance: Withstands long-term vibration and repeated bending while maintaining stable performance.

- Optimized Electrical Performance: Shorter circuit paths reduce current resistance, ensuring high-speed signal quality.

- High-Frequency Applications: Widely used in RF and high-speed mixed-signal designs.

Process overview

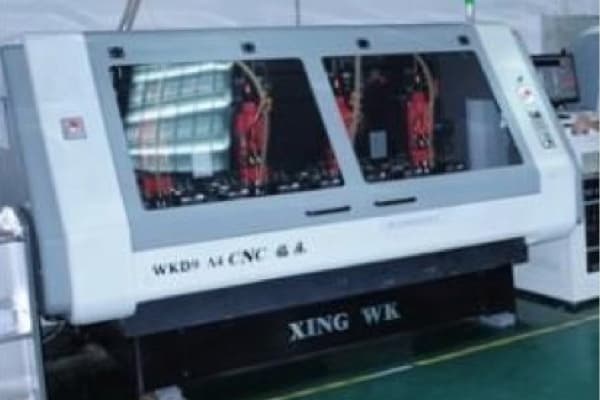

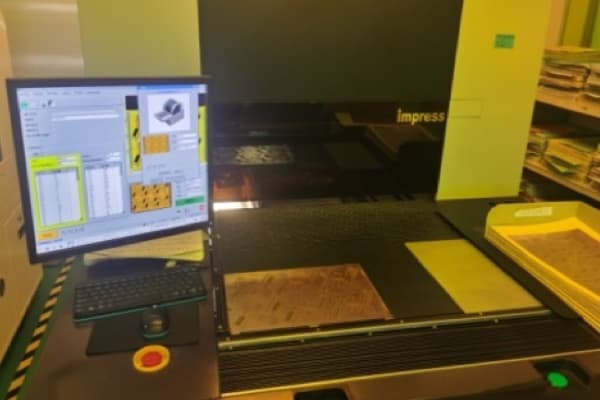

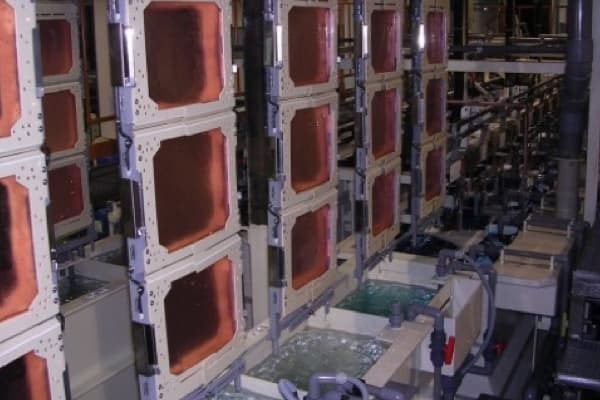

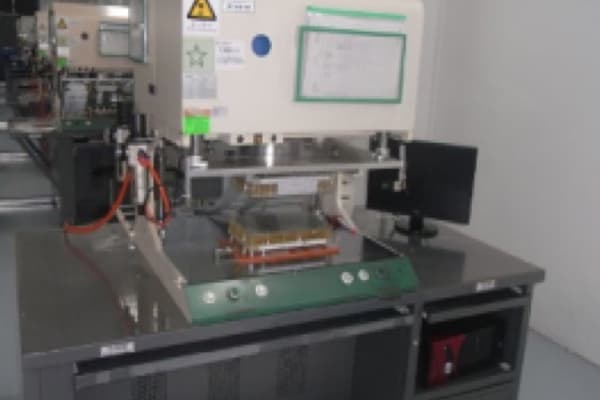

Process equipment

Sheer

Drill

Copper Plating

Exposuring

DES

AOI

Two Layer FPC Process

Alignment

Lamination Press

Copper Plating

Acid Dip(cleaning)

Surface Finished

Screen Printng

O_S Test

Punch

SMT

Assembly

Function Test